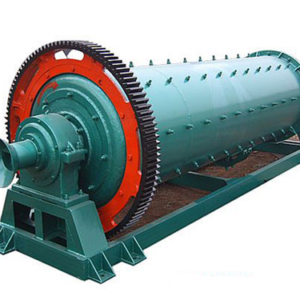

Silo for Cement Storage

Silo for bulk cement

Companies of the cement industry know how important a silo is that allows to store large amounts of cement without risk of accidents. This depends, in addition to a good silo design, a good execution of silk manufacturing. Therefore, it is important to buy a silo for cement that has special steel for heat reflection, that is coated with an anti-corrosive material, with relief in the welding of the parts of the silo, and that guarantees that there is no reaction between the cement and the walls of the silo. We know this because we are silo manufacturers in Brazil that have been in the market for more than 40 years. We have clients who demand the fabrication of metal structures in various segments, from mining to the civil and energy sector. Talk to our engineers about your silo warehouse projects, we’d love to hear more about it and how we could help design custom designs or not.

Cement silo with internal anti-corrosive paint.

Corrosion can alter the quality of the cement, influencing the strength of the constructions that use it. In addition, corrosion can cause losses in cement production, reflecting higher costs, thus impacting the profit of the cement manufacturer. Therefore, all our cement silos are manufactured as special anti-corrosive paint, ensuring that there is no damage during cement storage.

Cement metal silo with heat reflecting material

The silo for cement, to be used next to the concrete metering centre, can reach algae temperatures in regions where the sun is intense. Therefore, a special steel with heat shielding material is required during the fabrication of a silo design. For this reason, Viga offers experienced engineers to help you with which material to use in the manufacture of silos, specifically to the locality of your cement industry.

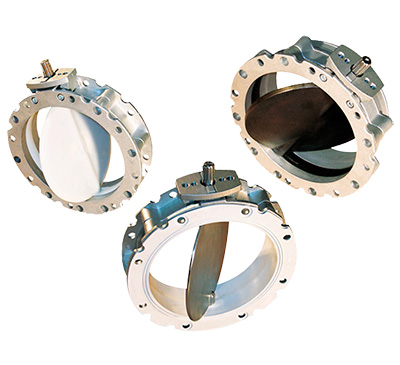

Cement silo coated with raised relief

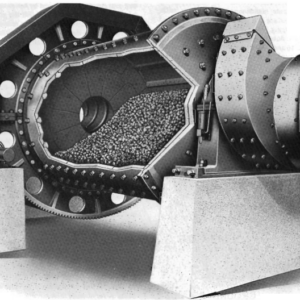

The way in which the cement silos are welded to one another may result in greater profits for the cement industry, since it avoids the need for a large amount of maintenance of the silo for cement, by means of the distribution of adequate pressure to the cement silos. silo walls for cement. There are cases where the silo, after a certain time of use burst due to use with volume at maximum capacity. Avoid accidents and do not take this risk. Prevent yourself!

Silo for cement with varied capacities

There are cement silos with varying size diameters, but the most common dimensions in silo designs for the cement industry are:

- silos with a diameter of 2,600 mm

- silos with a diameter of 3,000 mm

- silos with a diameter of 3,200 mm

- silos with a diameter of 3,200 mm

Avaliações

Não há avaliações ainda.